gearbox cvt Fundamentals Explained

gearbox cvt Fundamentals Explained

Blog Article

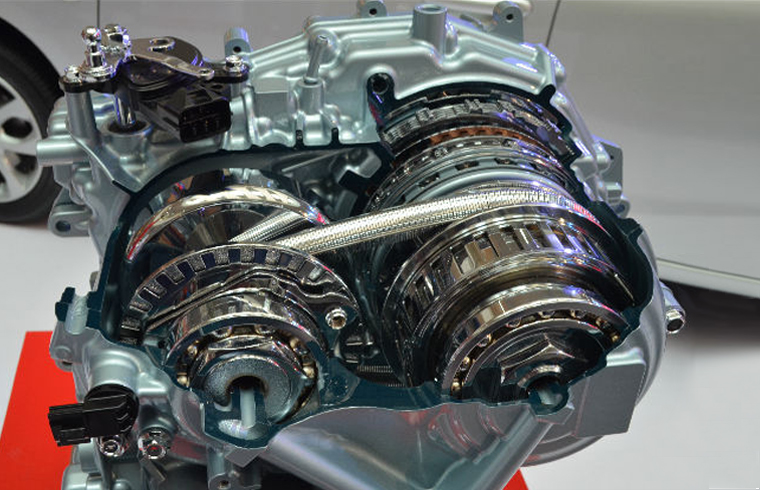

Pulley-centered CVTs are known for their effectiveness and smoothness, toroidal CVTs for his or her substantial torque capacity, and hydrostatic CVTs for his or her sturdiness and exact control in large machinery.

On the list of most important negatives of CVTs is that they can occasionally come to feel unresponsive or sluggish when accelerating from a end. This is because the transmission usually takes time to regulate the pulleys and belt to the proper ratio for your motor’s electric power output.

Your transmission complications are significantly reduced as a consequence of using hydraulics and elimination of friction-inclined factors of Get hold of.

These types of CVT devices use hydrostatic pumps and motors as constituent parts. The torque distribution is built attainable via fluid displacement and you've got a continuous variety of equipment ratios to pick from.

A gear going out just isn’t a problem having a continuously variable transmission mainly because it doesn’t have gears.

Probable Deal with: Test and substitute the transmission fluid, inspect and replace any worn parts, and tackle any inner harm Which might be triggering the noise.

If functionality isn’t your top rated precedence, you mainly use your vehicle all-around city and you simply don’t desire a handbook, then a CVT automatic could take advantage of sense. Driving lovers and those after the last word in refinement are read here very likely to favor another style of automatic gearbox.

A belt-pushed design presents close to 88% effectiveness,[four] which, although decrease than that of the manual transmission, could be offset by enabling the engine to run at its most successful RPM whatever the car or truck's velocity.

Normal Fluid Changes: CVT transmissions involve distinct varieties of fluid that should be checked and changed according to the company’s timetable. Utilizing the right fluid is significant, as the wrong style could cause considerable destruction.

Consistently Variable Transmission yang berarti Transmisi Variabel Kontinu adalah sistem mengubah rasio transmisi melalui penggunaan dua pulley (puli) dan sabuk baja. Sistem ini tidak memiliki gigi-gigi yang terdapat pada sistem transmisi otomatis konvensional atau handbook.

CVT transmissions operate about the theory of protecting the engine at its ideal velocity, often called the "energy band," for optimum effectiveness. Here is a simplified rationalization in their Procedure:

At the same time when this input pulley(sheave) moves, feeding output pulley(sheave) also moves and comes nearer to your mounted output pulley which in turn change the Section of v-shaped belt wrapped over the output pulleys toward the better cross-sectional region of your output conical pulleys and sought after torque ratios is attained.

The trick is, as a way to keep belt stress, the two pulleys need to act oppositely in unison. I guess just one pulley really should be actively diversified, even though another can use spring tension to shut the hole Hence preserving pressure.

The Handle process in a CVT employs sensors to observe the motor speed, motor vehicle velocity, and driver enter. The control procedure then makes use of this facts to regulate the pulley diameters and belt or chain tension to provide the ideal equipment ratio with the driving conditions.